A Sustainable Alternative to Palm-Based Surfactants

Novel Palm Oil-Free Ingredients Outperform Alternatives while Taking on Big Environmental Challenges in CPG Product Formulations

What do pastries, peanut butter, shampoo, cleaning products and biodiesel have in common? Each depends upon one common, highly pervasive ingredient: palm oil. Palm oil cuts across industry segments to find its way into roughly half the products found on supermarket shelves, most cosmetic brands and a variety of industrial products.

Palm oil-based ingredients initially were hailed as a sustainable alternative to petrochemical based ingredients. Yet the dark side of its meteoric rise links the palm oil industry to numerous serious environmental issues.

Oil palm plantations are responsible for the loss of tropical rainforests, which many endangered species, such as orangutans, rely upon for food and shelter. The forest loss not only harms biodiversity, but also adds to greenhouse gas (GHG) emissions, which impact climate change.

In addition, the palm oil industry and its supply chain are beset by labor issues, with numerous reports of both workforce labor and human rights abuses.

What is Palm Oil?

Palm oil is the most common type of vegetable oil in the world, sourced from the pulp of palm oil tree fruit. A native African plant, palm oil trees are now cultivated in other countries that lie within ten degrees of the equator, or the optimal zone for their growth. Palm oil is included as an ingredient in more than half of all packaged products sold in America, including food, but also cosmetics, soaps and detergents.

Some sources state that while palm oil use is destructive to the environment, no other oilseed crop can match its yield per acre. This argument has merit when considering palm oil in terms of crop productivity: it supplies 36% of the world’s oil but uses less than 9% of croplands devoted to oil production.

This argument however dismisses the ecological impact of palm oil deforestation linked to its cultivation, while also overlooking any potential, more sustainable palm oil alternatives. Tropical rainforests act as vast carbon storehouses, rich in biological diversity. The increasing demand for palm-based products threatens their existence and has a negative impact on the climate.

Exponential Demand for Palm Oil

According to USDA crop analysis, palm oil production exploded from 5 million tons globally in 1999 to 72 million tons today. The U.S. alone registered a 900 percent spike in demand during that period. By the year 2050, palm oil production is expected to quadruple.

This spike in demand is tied to its versatility. Palm oil is used as a feedstock in 20-24% of the global surfactants market used in industrial applications and consumer products. For example, palm oil derivatives in the form of surfactants and emulsifiers appear in at least 70% of all cosmetics. In total, chemical uses comprise a quarter of global palm oil demand.

This spike in demand is tied to its versatility. Palm oil is used as a feedstock in 20-24% of the global surfactants market used in industrial applications and consumer products. For example, palm oil derivatives in the form of surfactants and emulsifiers appear in at least 70% of all cosmetics. In total, chemical uses comprise a quarter of global palm oil demand.

Increased palm demand has subsequently led to increased land use for its production. Since 1980 the amount of land used to grow palm has more than quadrupled from 4 million to 19 million hectares in 2018. Indonesia and Malaysia account for 63% of global land use for palm, accounting for 84% of the world’s production.

Environmental Impacts of Palm Oil Production

Loss of Biodiversity

The zone of optimal conditions for producing palm oil lies 10 degrees on either side of the equator, partly explaining its predominance in Indonesian and Malaysian agriculture. The level of biodiversity in a tropical rainforest is much higher than other types of ecosystems, with the richest terrestrial biome on the planet. According to the Nature Conservancy, fifty percent of all known species of plants and animals live in a rainforest.

The palm industry utilizes 10% of all agricultural cropland today, and is projected to grow by 400% by 2050.

And while the industry is working on improving their sustainability profile, only 20% of industry capacity is RSPO certified. Each year only half of all RSPO palm oil is sold as certified RSPO, with the remaining 10% sold as traditional palm oil.

Greenhouse Gas Emissions (GHG)

Tropical rainforests occupy approximately 15% of all global land area, yet they store two-thirds of all the carbon in their terrestrial vegetation. However, the peat soils underneath can contain even more carbon—as much as 18 to 28 times that of the forests themselves.

In what’s known as “slash-and-burn” agriculture, individual farmers and larger organizations alike cut down palm, burn the rainforest and drain peatlands to clear the land for palm oil cultivation. In fact, 80% of the fires set in Indonesia are specifically linked to palm oil planting. Some of the world’s largest fires have occurred on drained peatland, releasing hundreds of years’ worth of sequestered carbon over a relatively brief period. The palm industry generates 1.4% of all global C02 annually – for perspective, the global aviation industry generates 2.5% of CO2 emissions.

Carbon is not the sole greenhouse gas (GHG) emitted by palm oil plantations. Scientific literature about its cultivation mentions the heavy doses of nitrogen fertilizer used on oil palm plantations. The fertilizers crucial to palm production account for 50-70% of field operational costs.

This subsequently contributes to another type of GHG emission, with one article stating that 48.7% of the GHG emitted to produce 1 t of palm oil fruit is due to nitrogen fertilization. Nitrous oxide is a potent GHG, 300 times more harmful than carbon dioxide.

In addition to nitrous oxide emissions, the soil erosion from palm oil cultivation, coupled with the intense seasonal rainfalls common to the tropics, increase nutrient loss, leaching and runoff. These byproducts of palm oil cultivation compound existing environmental issues.

Biosurfactants: A Revolutionary yet Practical Palm Oil Substitute Ingredient

Articles about sustainable palm oil revolve around a central belief that only another oilseed crop can substitute for palm oil functionality. They outline common difficulties related to its substitution in industrial processes and products such as soaps, detergents, or cosmetics. But now a new, completely palm-free ingredient has been commercialized.

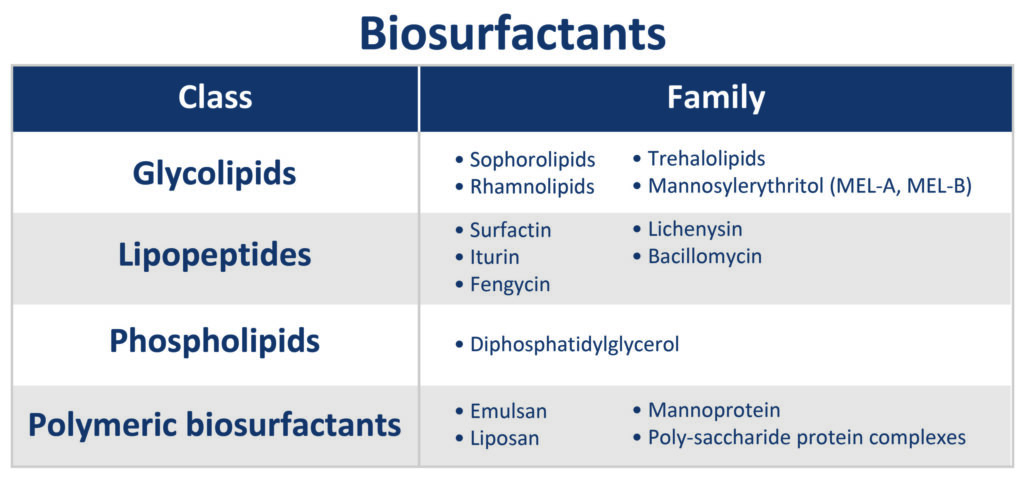

Enter biosurfactants, sustainable ingredients created using fermentation processes that can replace palm-based ingredients and chemical surfactants. The anionic surfactant market, for example, is projected to reach 20.1 billion U.S. by 2022. This is the most common type of surfactant utilized for home and personal care products, currently dominated by oleochemical or petrochemical sources.

Biosurfactant Ingredients are Sustainable, Powerful and Multifunctional

Locus Ingredients has developed a patented production process using bioinformatics and fermentation technology to develop nature-derived biosurfactants—specifically, sophorolipids, a biosurfactant from the glycolipid class. The novel fermentation-produced biosurfactant ingredients provide unmatched sustainability and multifunctionality combined with performance improvements for product formulations that span personal care, home care and industrial applications.

Biosurfactants as a category overall present formulators with attractive advantages over synthetic surfactants and other bio-based surfactants; and can act as palm oil alternatives in industrial applications and CPG product formulations. Fermentation-produced biosurfactants offer characteristics such as extremely low toxicity, high biodegradability and better multifunctionality compared to alternatives; plus more mechanisms of action, lower aquatic toxicity and a higher degree of overall safety.

Locus Ingredients’ biosurfactants specifically are fermented using completely renewable raw materials and are USDA certified as 100% biobased. The ingredients offer formulators a near-zero carbon footprint and greater functionality than comparable alternative ingredients, offering superb wetting, emulsification, scouring and degreasing, as well as broad multifunctionality, allowing 100% sustainable formulations with fewer ingredients.

Locus Ingredients attains the necessary regulatory certifications and/or approvals in order to provide manufacturers with multiple use options. Amphi® M as one example, is a TSCA (Toxic Substances Control Act) approved biosurfactant designed for household and industrial products. It can act as a multifunctional emulsifier, degreaser, defoaming agent, porous surface cleaning booster, pine oil and d-limonene solubilizer, odor preventer and more in both nonionic and ionic applications.

Scaling Biosurfactant Use to Replace Palm Oil Ingredients

Previously, manufacturers were unable to adopt the use of biosurfactants in formulations due to the expense and lack of available volume. Locus Ingredients produces its sophorolipid ingredients in scalable modular reactors at competitive costs and in a fraction of the standard time to market. This helps facilitate rapid market penetration and accelerates their use as alternatives to palm oil ingredients.

Locus Ingredients’ production facilities can be built anywhere in the world where there is water and electricity, in months rather than years. Local communities can be utilized and trained in biosurfactant production—since the fermenters do not require an advanced degree to operate. This safety and flexibility, combined with rapid scalability, means that Locus Ingredients’ biosurfactants can be produced in the volumes required for formulators anywhere around the globe to replace palm oil ingredients, while supporting the local economy.

Locus Ingredients offers manufacturers sustainable options that answer multiple palm oil challenges, working to end palm oil deforestation, supply affordable clean, green palm alternatives and exceed performance expectations on the part of the end user. Science is only beginning to scratch the surface of the full potential of biosurfactants. Fermentation-produced biosurfactants from Locus Ingredients help create cleaner, greener product formulations. This simple change can slow deforestation from palm oil usage and eliminate toxic or trace chemicals linked to synthetic surfactants, without sacrificing performance, price point or profitability.

READ MORE: Could Your Detergent Be Harmful? Exploring The Dangers Of Ethoxylated Ingredients

For consumers, understanding the presence of ethoxylated surfactants is not just about informed purchasing—it’s about safeguarding personal health. These compounds often find their way into skincare products, detergents and other household staples. However, concerns loom over their potential to cause skin irritation, allergic reactions and even contribute to long-term health issues. The need for transparency in labeling is critical, allowing consumers to make choices aligned with their well-being. [Read the full article here]