Could Your Detergent Be Harmful? Exploring the Dangers of Ethoxylated Ingredients

In the world of consumer products, ethoxylated ingredients often lurk beneath innocuous labels, their presence pervasive but their implications not always apparent. Born from the process of ethoxylation, these compounds serve as workhorses in industries ranging from personal care to household cleaning, pharmaceuticals and more. Yet, while they offer utility, a closer examination reveals potential concerns that consumers should be aware of when buying products.

For consumers, understanding the presence of ethoxylated surfactants is not just about informed purchasing—it’s about safeguarding personal health. These compounds often find their way into skincare products, detergents and other household staples. However, concerns loom over their potential to cause skin irritation, allergic reactions and even contribute to long-term health issues.

The need for transparency in labeling is critical, allowing consumers to make choices aligned with their well-being.

Furthermore, environmentalists highlight the ecological repercussions of ethoxylated surfactants. While they enhance product performance, their persistence in the environment raises alarms about bioaccumulation and toxicity to aquatic life. With each rinse down the drain, these compounds have the potential to leave lasting footprints on ecosystems, underscoring the importance of responsible usage and disposal practices.

What are Ethoxylated Ingredients?

Ethoxylated ingredients are a diverse group of compounds that undergo a chemical process known as ethoxylation wherein ethylene oxide (EO) reacts with various compounds, typically alcohols or phenols, under controlled conditions. This reaction results in the attachment of ethylene oxide molecules to the original compound, yielding ethoxylated ingredients with altered properties. While this transformation grants them desirable traits like surfactancy and solubility, it also raises red flags due to associated risks.

Ethoxylation Production Process

Ethoxylated ingredients are produced through a multi-step process that begins with the selection of a suitable substrate, such as fatty alcohols, phenols or amines. These substrates undergo ethoxylation by being exposed to ethylene oxide gas in the presence of a catalyst, typically an alkaline or acidic catalyst. The reaction conditions, including temperature, pressure and catalyst concentration, are carefully controlled to ensure optimal yield and product quality.

After ethoxylation, the resulting ethoxylated compounds undergo purification to remove any unreacted starting materials or byproducts. This purification process may involve distillation, filtration or other separation techniques to obtain the desired purity and composition of the final product.

Common Examples of Ethoxylated Ingredients

Ethoxylated ingredients are widely used across various industries for their versatile properties and applications. Some common examples include:

- Surfactants: Ethoxylated surfactants, such as sodium laureth sulfate and nonylphenol ethoxylates, are widely used in household cleaners, personal care products and industrial formulations for their ability to reduce surface tension and facilitate the dispersion of substances in liquids.

- Emulsifiers: Ethoxylated emulsifiers, such as polysorbate 80 and sorbitan oleate ethoxylate, are employed in food, pharmaceuticals and cosmetics to stabilize oil-in-water or water-in-oil emulsions, allowing for the creation of uniform and stable formulations.

- Solvents: Ethoxylated solvents, such as ethoxylated alcohols and glycol ethers, find applications in paints, coatings and cleaning products due to their solubilizing and dispersing properties, which enable the dissolution of various substances in liquid formulations.

These examples illustrate the diverse range of ethoxylated ingredients and their importance in numerous industries. Despite their widespread use, concerns regarding safety, environmental impact and regulatory oversight highlight the need for continued research and scrutiny in the formulation and usage of ethoxylated compounds.

Ethoxylated Surfactants: A Closer Look

Ethoxylated surfactants represent a subset of ethoxylated ingredients, forged through the marriage of ethylene oxide with surfactant precursors. Surfactants, short for surface-active agents, play a vital role in numerous consumer products, facilitating the removal of dirt and grease by lowering surface tension. Ethoxylation amplifies their efficacy, rendering them indispensable in the formulation of household cleaners, shampoos and cosmetics.

Despite their utility, ethoxylated surfactants come laden with concerns. Chief among them is the potential for contamination with impurities such as 1,4-dioxane, a known carcinogen. This byproduct of the ethoxylation process lurks surreptitiously in many ethoxylated formulations, evading detection on ingredient labels. Exposure to 1,4-dioxane through everyday products poses a silent threat to consumer health, prompting calls for stricter regulations and heightened vigilance.

Consumers must navigate this landscape armed with knowledge, discerning between products that prioritize safety and those that prioritize efficacy at any cost. With ethoxylated surfactants under scrutiny, the onus falls on both manufacturers and consumers to seek out alternatives that offer performance without compromising well-being or the environment.

By fostering transparency and demanding accountability, consumers can wield their purchasing power to drive positive change and foster a marketplace that prioritizes health and sustainability.

Where are Ethoxylated Ingredients found?

Ethoxylated ingredients find wide-ranging applications across diverse industries, their versatility and functional properties making them indispensable in the formulation of countless consumer products. From enhancing the efficacy of personal care items to improving the performance of industrial cleaners, their utility spans across various sectors, each benefiting from their unique attributes.

Cosmetics Industry

In the realm of cosmetics, ethoxylated ingredients play a multifaceted role, contributing to the formulation of skincare products, hair care treatments and decorative cosmetics. Ethoxylated surfactants, for instance, are prized for their emulsifying properties, enabling the creation of stable formulations that deliver active ingredients effectively. Additionally, ethoxylated emollients impart a luxurious texture to creams and lotions, enhancing their spreadability and moisturizing capabilities.

Household Products

Household cleaners owe much of their efficacy to ethoxylated surfactants, which serve as the backbone of formulations designed to tackle dirt, grease and stains. These compounds reduce surface tension, allowing water and detergent molecules to penetrate and lift grime from various surfaces. In laundry detergents, ethoxylated ingredients help disperse soils and prevent re-deposition on fabrics, ensuring a thorough clean with minimal effort.

Pharmaceuticals

In the pharmaceutical industry, ethoxylated ingredients find application in both medicinal formulations and drug delivery systems. Ethoxylated excipients aid in solubilizing active pharmaceutical ingredients (APIs), enhancing their bioavailability and ensuring uniform dosage delivery. Moreover, ethoxylated compounds serve as emulsifiers and stabilizers in topical medications and ointments, facilitating drug absorption and improving patient compliance.

Agrochemicals

Ethoxylated ingredients play a crucial role in the agricultural sector, where they feature prominently in the formulation of pesticides, herbicides and fertilizers. Surfactant-based formulations improve the spread and adherence of active ingredients on plant surfaces, enhancing their efficacy while minimizing environmental impact. Ethoxylated adjuvants also help mitigate the effects of hard water, ensuring consistent performance in diverse agricultural settings.

Food Industry

In the food industry, ethoxylated ingredients find application in food processing, packaging and preservation. Ethoxylated emulsifiers aid in the creation of stable emulsions and foams, enhancing the texture and mouthfeel of processed foods such as sauces, dressings, and baked goods. Additionally, ethoxylated compounds serve as defoaming agents in food processing equipment, ensuring efficient operation and product quality.

The widespread adoption of ethoxylated ingredients underscores their value and versatility in meeting the diverse needs of modern industries. However, as their usage proliferates, it becomes imperative to consider the potential implications for consumer health and environmental sustainability. By promoting responsible usage and exploring alternative formulations, industries can harness the benefits of ethoxylated ingredients while mitigating associated risks, ensuring a safer and more sustainable future for all.

Are Ethoxylated Ingredients Safe?

Ethoxylated ingredients, despite their widespread use and utility, come under scrutiny due to potential safety concerns that consumers and regulatory bodies alike must address. While these compounds offer valuable functional properties, understanding their potential risks is paramount to safeguarding public health and well-being.

Ethoxylated ingredients have been associated with the presence of 1,4-dioxane, a potentially harmful byproduct of the ethoxylation process. Here’s how ethoxylated ingredients and 1,4-dioxane are linked:

- Formation during Ethoxylation: 1,4-dioxane can be formed as a trace contaminant during the ethoxylation process. Ethylene oxide, the key component in ethoxylation, can react with small amounts of precursor compounds containing 1,4-dioxane impurities, leading to its formation in ethoxylated products.

- Persistence in Products: Once formed, 1,4-dioxane can persist in finished products containing ethoxylated ingredients. It is often present as a contaminant rather than an intentionally added ingredient, making it challenging to detect and remove during manufacturing processes.

- Health Concerns: 1,4-dioxane is classified as a probable human carcinogen by the International Agency for Research on Cancer (IARC). Prolonged exposure to 1,4-dioxane through the use of products containing ethoxylated ingredients has raised concerns about potential health risks, including cancer and adverse effects on the liver and kidneys.

- Regulatory Oversight: Regulatory agencies, such as the U.S. Food and Drug Administration (FDA) and the European Chemicals Agency (ECHA), have established guidelines and regulations to limit the presence of 1,4-dioxane in consumer products. However, monitoring and enforcement of these regulations vary, and trace amounts of 1,4-dioxane may still be found in some ethoxylated products.

- Consumer Awareness: Consumer advocacy groups and organizations have raised awareness about the presence of 1,4-dioxane in ethoxylated products and have called for stricter regulations and improved labeling practices to inform consumers about potential risks. Some brands have responded by voluntarily testing and reformulating their products to reduce or eliminate 1,4-dioxane contamination.

In summary, while ethoxylated ingredients offer valuable properties in various consumer products, their association with 1,4-dioxane contamination underscores the importance of rigorous quality control measures and regulatory oversight to ensure product safety. Consumers are encouraged to stay informed, read product labels carefully and support brands committed to transparency and safety in ingredient sourcing and formulation.

How to Spot Ethoxylated Ingredients on Product Labels

Consumer awareness regarding the presence of ethoxylated ingredients in everyday products is paramount for making informed choices that align with personal health and environmental values. As consumers become more conscientious about the ingredients they expose themselves to, understanding how to identify ethoxylated compounds on product labels becomes increasingly important.

Many consumers may not be aware of the prevalence of ethoxylated ingredients in a wide range of household items, cosmetics and personal care products. However, given the potential health and environmental concerns associated with these compounds, educating consumers about their presence and implications is crucial.

By understanding the role of ethoxylated ingredients and their potential effects on health and the environment, consumers can make more informed purchasing decisions. This awareness empowers individuals to choose products that align with their values, whether prioritizing natural alternatives, supporting brands with transparent labeling practices or advocating for stricter regulatory standards.

Consumers can find ethoxylated ingredients on product labels by looking for specific chemical names, abbreviations or suffixes commonly associated with ethoxylated compounds. Here are some tips to help identify ethoxylated ingredients on product labels:

- Look for “PEG” or “Polyethylene Glycol”: Ethoxylated compounds are often listed with the prefix “PEG” (Polyethylene Glycol) followed by a number, which indicates the degree of ethoxylation. For example, “PEG-40” indicates a polyethylene glycol compound that has undergone 40 ethoxylation steps.

- Check for “Eth” or “Ethoxylate” Suffixes: Ingredients with names ending in “eth” or “ethoxylate” are likely ethoxylated compounds. For instance, “Laureth sulfate” or “Ceteareth” are examples of ethoxylated surfactants commonly used in personal care products.

- Watch for Other Abbreviations: Some ethoxylated ingredients may be listed using other abbreviations, such as “EO” (ethylene oxide) or “POE” (polyoxyethylene). Keep an eye out for these abbreviations in ingredient lists.

- Be Aware of Synonyms: Ethoxylated ingredients may also be referred to by trade names or synonyms that may not explicitly include “PEG” or “eth” suffixes. Familiarize yourself with common ethoxylated compounds and their alternative names. For example, SLES may be referred to as “non-ionic surfactant.”

- Look for Certification Labels: Some products may bear certification labels indicating that they are free from ethoxylated ingredients or have been certified as environmentally friendly. Look for labels such as “PEG-free,” “Ethoxylate-free” or certification logos from organizations promoting sustainable and natural products.

- Check for Transparency Statements: Some brands may voluntarily disclose the absence or presence of ethoxylated ingredients on their product labels or websites. Look for statements indicating transparency in ingredient sourcing and formulation.

By paying attention to ingredient labels and understanding common names and abbreviations associated with ethoxylated compounds, consumers can make more informed choices about the products they use and support brands aligned with their values regarding safety and sustainability.

As consumer demand for transparency and safer products continues to grow, advocacy for clearer labeling standards and greater ingredient transparency remains critical. By staying informed and actively supporting initiatives that promote clearer labeling and safer product formulations, consumers can drive positive change and contribute to a marketplace that prioritizes health, sustainability and accountability.

Case Study: Ethoxylated Ingredients and the Palm Oil Value Chain

Palm oil plays a significant role in the production of ethoxylated ingredients, particularly in the context of surfactants and emulsifiers. Palm oil and its derivatives are commonly used as feedstocks in the synthesis of ethoxylated compounds due to their abundance, cost-effectiveness and versatile chemical properties.

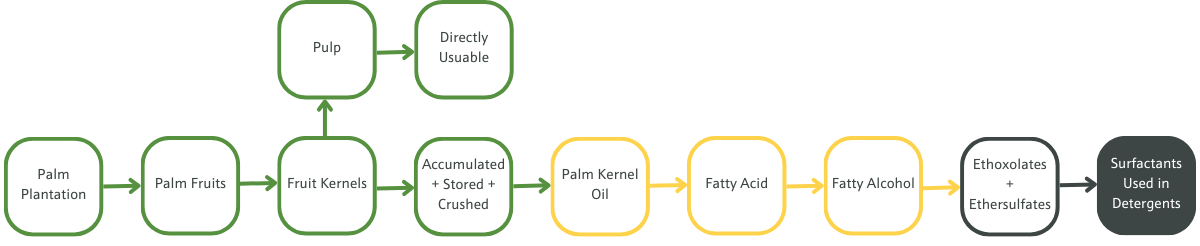

Figure 1: Processing Palm Kernels to Surfactants

In the ethoxylation process, palm oil or palm kernel oil may serve as substrates for ethoxylation reactions, where ethylene oxide molecules are added to the fatty acid chains present in the oil. This reaction yields ethoxylated fatty acids or ethoxylated fatty alcohols, which are widely used as surfactants and emulsifiers in various industries, including personal care, household cleaning and agrochemicals.

Palm oil-derived ethoxylated ingredients offer several advantages, including their excellent surfactant properties, biodegradability and compatibility with a wide range of formulations. Additionally, palm oil’s high yield per hectare makes it an attractive option for large-scale production, meeting the demand for ethoxylated ingredients in global markets.

However, the widespread use of palm oil in the production of ethoxylated ingredients has raised environmental concerns, particularly regarding deforestation, habitat destruction and biodiversity loss in regions where palm oil plantations are expanding. The unsustainable practices associated with palm oil production, including land clearing, use of chemical fertilizers and pesticides and carbon emissions from land conversion, contribute to environmental degradation and greenhouse gas emissions.

As a result, there is growing pressure on industries to adopt sustainable sourcing practices for palm oil and its derivatives, including the production of ethoxylated ingredients. Efforts to promote sustainable palm oil production, such as certification schemes (e.g., Roundtable on Sustainable Palm Oil), purport to support the conservation of forests, protection of wildlife habitats and adherence to social and environmental standards throughout the palm oil supply chain.

Roundtable on Sustainable Palm Oil

The Roundtable on Sustainable Palm Oil (RSPO) was established in 2004 as a multi-stakeholder initiative aimed at promoting the production and use of sustainable palm oil. While the RSPO has made strides in addressing some of the environmental and social challenges associated with palm oil production, there are several issues and criticisms surrounding the organization:

- Lack of Enforcement: One of the primary criticisms of the RSPO is its perceived lack of enforcement mechanisms. Despite having standards and criteria for sustainable palm oil production, there have been instances where member companies have been accused of non-compliance with these standards without facing significant consequences.

- Greenwashing: Some critics argue that the RSPO certification process allows companies to engage in “greenwashing” – using the RSPO label to present themselves as environmentally responsible without making meaningful changes to their practices. This undermines the credibility of the certification and dilutes its impact.

- Limited Scope: The RSPO standards primarily focus on environmental criteria such as deforestation and biodiversity conservation, with less emphasis on social and labor-related issues. This narrow focus may overlook critical social concerns such as land rights conflicts, labor exploitation and human rights abuses in palm oil-producing regions.

- Certification Costs: Obtaining RSPO certification can be costly for smallholders and independent growers, posing a barrier to entry for those seeking to adopt sustainable practices. This cost burden disproportionately affects small-scale farmers and may hinder their ability to participate in the certification process.

- Transparency and Accountability: There have been concerns about transparency within the RSPO, particularly regarding decision-making processes and the disclosure of information related to member companies’ operations. Critics argue that greater transparency and accountability are needed to ensure the integrity of the RSPO certification system.

- Continued Deforestation: Despite the RSPO’s efforts to promote sustainable palm oil production, deforestation and habitat destruction associated with palm oil cultivation continue in some regions. This raises questions about the effectiveness of the RSPO in achieving its conservation goals and reducing the environmental impact of palm oil production.

Overall, while the RSPO has played a significant role in raising awareness about sustainable palm oil only a fraction of palm oil sold globally adheres to the standards set by the RSPO, highlighting a significant gap between demand and certified supply.

Shockingly, only one-fifth of the total palm oil produced worldwide is certified by the RSPO. Even more concerning is the fact that of this already limited RSPO-certified palm oil, only half is actually sold as RSPO-certified, with the remaining 10% being sold as traditional palm oil.

This discrepancy underscores the challenges in ensuring that palm oil production aligns with sustainability principles, despite the efforts of certification bodies like the RSPO. It suggests that while there is growing awareness and recognition of the need for sustainable palm oil, there are still significant barriers to its widespread adoption and market penetration.

Focusing on sustainable ingredient alternatives rather than solely relying on responsibly sourced palm oil is crucial for several reasons.

Firstly, while responsibly sourced palm oil addresses some environmental and social concerns, it does not fully mitigate the negative impacts associated with palm oil production, such as deforestation, habitat loss and greenhouse gas emissions. Sustainable ingredient alternatives, such as biosurfactants, offer the opportunity to reduce reliance on palm oil altogether, thereby minimizing its environmental footprint.

Additionally, diversifying ingredient sources promotes innovation and resilience within industries, reducing reliance on monocultures and contributing to greater biodiversity conservation.

Moreover, sustainable ingredient alternatives often come with additional benefits such as improved performance, lower toxicity and higher biodegradability, offering a more holistic solution to sustainability challenges.

By prioritizing the development and adoption of sustainable alternatives, industries can move towards more environmentally friendly and socially responsible practices, ultimately contributing to a more sustainable future for both ecosystems and communities worldwide.

In summary, palm oil serves as a crucial feedstock for the production of ethoxylated ingredients, contributing to their widespread availability and functionality. However, the environmental and social impacts associated with palm oil production not only underscore the importance of sustainable sourcing practices and responsible consumption in mitigating the negative effects of palm oil-derived ethoxylated ingredients on the environment and local communities, but that more sustainable alternatives are needed.

Are There Safer Alternatives to Ethoxylated Ingredients?

As awareness of the environmental and health concerns associated with ethoxylated ingredients grows, industries are increasingly turning to alternative solutions that prioritize sustainability and safety. From embracing green chemistry principles to harnessing the power of nature’s own solutions, the quest for alternatives to ethoxylated compounds is driving innovation and shaping sustainable practices across various sectors.

Exploring Natural Alternatives

Plant-derived ingredients such as saponins, derived from sources like soapnuts and yucca plants, offer natural surfactant properties without the need for ethoxylation. These botanical alternatives not only provide effective cleaning and foaming capabilities but also boast biodegradability and low environmental impact, making them ideal choices for eco-conscious consumers and industries.

Biosurfactants

One promising avenue for replacing ethoxylated ingredients lies in the realm of natural alternatives, including bio-based and plant-derived compounds. Biosurfactants, for example, offer a renewable and environmentally friendly alternative to synthetic surfactants derived from ethoxylation processes. These microbial-produced surfactants exhibit excellent surface-active properties while being biodegradable and less toxic to aquatic life. By harnessing the power of microorganisms, industries can reduce their reliance on ethoxylated surfactants and embrace more sustainable solutions.

Adopting Green Chemistry Principles

Green chemistry, with its focus on designing chemical products and processes that minimize environmental impact, offers another avenue for reducing reliance on ethoxylated ingredients. By optimizing chemical reactions, minimizing waste generation and prioritizing renewable feedstocks, green chemistry principles enable the development of sustainable alternatives that meet performance requirements while mitigating environmental risks.

One example of green chemistry in action is the synthesis of surfactants using enzymatic catalysis or biocatalysts instead of traditional chemical methods. These enzymatic approaches offer higher selectivity, lower energy consumption and reduced environmental footprint compared to conventional processes, paving the way for greener surfactant production.

Sustainable Practices in Industry

Beyond seeking alternative ingredients, industries are also adopting sustainable practices to minimize their environmental impact throughout the product lifecycle. From sourcing renewable raw materials to optimizing manufacturing processes and reducing waste, sustainable initiatives are integral to responsible business practices.

For instance, companies are increasingly sourcing renewable feedstocks, such as plant-based oils and sugars, as alternatives to petroleum-derived precursors for ethoxylation. By embracing renewable resources, industries can reduce their dependence on fossil fuels and mitigate greenhouse gas emissions associated with chemical production.

Furthermore, efforts to minimize waste generation and promote circularity are gaining traction across industries. From implementing closed-loop manufacturing processes to developing innovative recycling and recovery technologies, companies are striving to minimize their environmental footprint and maximize resource efficiency.

In conclusion, the quest for alternatives to ethoxylated ingredients is driving innovation and sustainability across industries. By exploring natural alternatives, adopting green chemistry principles, and embracing sustainable practices, industries can reduce their reliance on ethoxylated compounds and pave the way for a more environmentally friendly and socially responsible future.

The Dark Side Of 1,4-Dioxane: Why Safer Alternatives Are A Must

READ MORE: What Is 1,4-Dioxane?

1,4-Dioxane comes from ethoxylated surfactants, legacy formulation ingredients that are used to improve water solubility and provide a stable foam to cleaning products. However, the production of ethoxylated surfactants entails the risk of producing the toxic, hard to separate byproduct.

While once considered an invaluable stabilizer for chlorinated solvents, specifically those used in deep cleaning of industrial machinery, 1,4-dioxane has become a particularly controversial chemical2. While not acutely toxic (LD50 = 5200 mb/kg in rats), 1,4-dioxane is an irritant and classified by numerous regulatory bodies as either a probable or known carcinogen. [Read the full article here]