Which Natural Surfactants are Superior: Biosurfactants or Bio-based Surfactants?

Discover the sustainability and performance differences that make microbial biosurfactants (produced through fermentation) the premium choice for industrial and CPG surfactant applications

Surfactants are compounds that are commonly used in a wide range of product formulations. Many of these product formulations use chemical surfactants, meaning they’re sourced from non-renewable, petroleum-based raw materials and feedstocks. In an effort to increase environmental responsibility while meeting regulatory requirements and stakeholder demands, surfactant producers have started to replace petrochemical-based raw materials with bio-based, renewable feedstocks. These sustainable replacements to chemically based surfactants are known as bio-based surfactants.

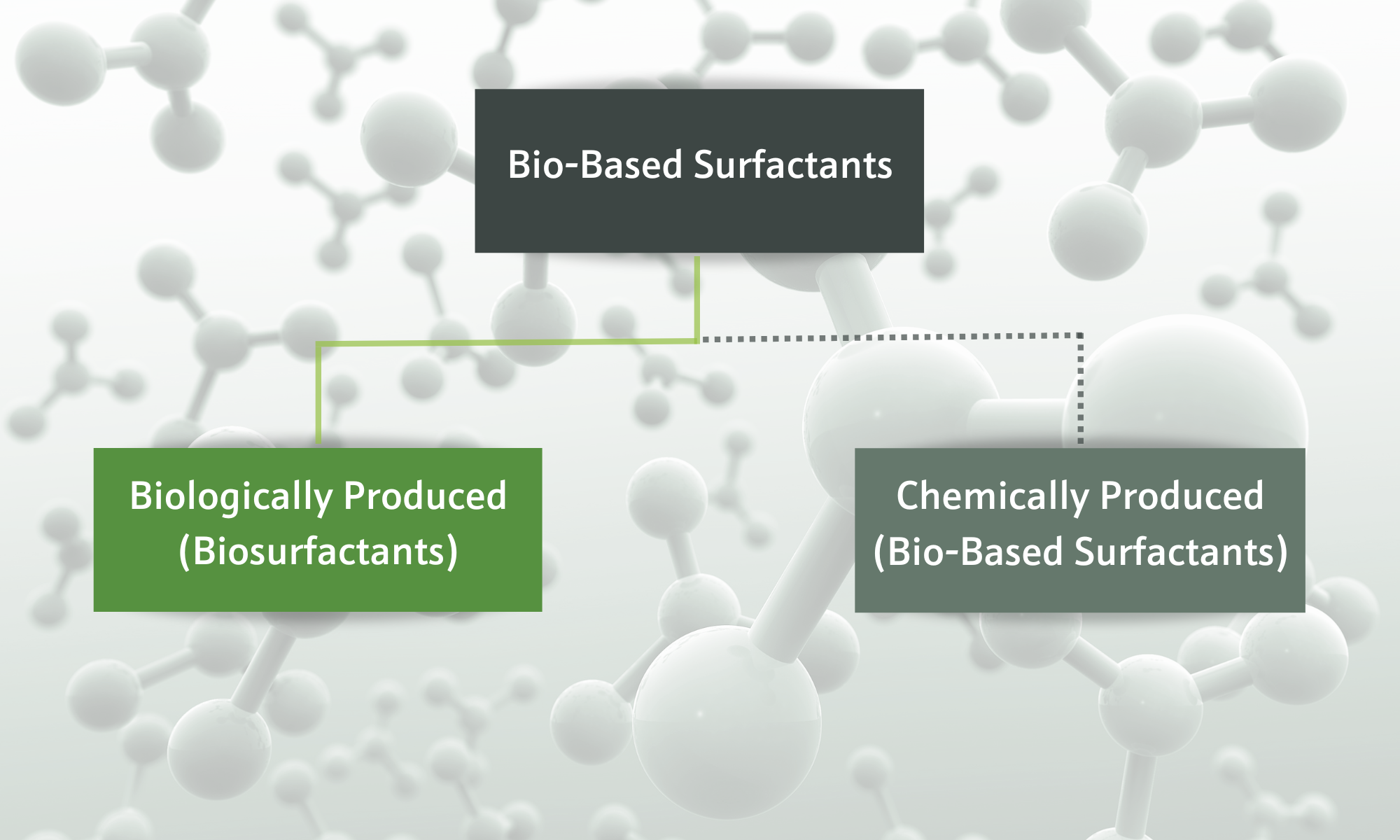

However, not all bio-based surfactants are created equally. There are different types of bio-based surfactants that have different levels of sustainability. The most sustainable of which is a classification known as biosurfactants.

Bio-based surfactants, biosurfactants…what’s the difference? Unsurprisingly, with these new developments has come confusion in terminology, both with product formulators as well as among end users.

There are key characteristics that differentiate legacy, petrochemical surfactants from bio-based surfactants, as well as chemically manufactured bio-surfactants from their biologically created or fermentation produced counterparts, biosurfactants.

What are Bio–Based Surfactants?

The USDA defines bio-based surfactants as those that are derived “… in whole or significant part of biological products or renewable domestic agricultural materials (including plant, animal, and marine materials) or forestry materials.”

In short, all bio-based surfactants are created at least in part from bio-based, renewable feedstocks and raw materials.

Applications of bio-based surfactants span most surfactant market sectors. They are found in laundry detergents, foods, cosmetics, personal care products, pharmaceuticals, paints and coatings, environmental remediation treatments and industrial applications.

Bio-based surfactants derived from fatty acids and neutral lipids are increasingly popular due to their favorable performance, biodegradability, biocompatibility, and their potential replacement of fossil fuel-derived surfactants. Many consumers prefer buying goods containing bio-based surfactants in an effort to shop sustainably and reduce their personal carbon footprint.

However, there are two key things to know about bio-based surfactants:

1.) Some Bio-based Surfactants Are Chemically Produced

Manufacturers of bio-based surfactants advertise their products as a sustainable alternative to synthetic or chemical surfactants. However, the production of many bio-based surfactants requires traditional chemical reactions. These reactions consume substantial levels of heat and electricity generated by hydrocarbon sources—leaving a larger carbon footprint.

“By developing their bio-based surfactants using processes that require fossil fuels, the sustainability claims of many manufacturers are negated.”

For example, many key manufacturers in the global biosurfactant market produce alkyl polyglucosides (APGs) and glucamides—well-known bio-based surfactants that are sugar-based—at an industrial scale. Both APGs and glucamides are developed using renewable starting materials (such as glucose, fatty alcohols, and triglycerides). However, like conventional surfactants, both ingredients are synthetically produced using chemical reactions.

By developing their bio-based surfactants using processes that require fossil fuels, the sustainability claims of many manufacturers are negated.

2.) Bio-based Surfactants Are Not Always 100% Biobased

While all bio-based surfactants contain carbon derived from renewable sources, some also contain carbon from fossil fuels. Classifications have been developed to rank bio-based surfactants based on their starting materials. Two examples include:

- The Renewable Carbon Index (RCI), which grades bio-based surfactants based on their bio content, or the percentage of total carbon derived from plant or agricultural-based sources as opposed to carbon from fossil fuels.

- The European Commission of Standardization (CEN), which classifies surfactants into four categories based on the percentage of renewable carbon (carbon derived from renewable feedstocks) that they contain.

Classifications like these allow surfactants to be categorized as fully bio-based even if they contain fossil-fuel based materials. For example, CEN considers a surfactant “wholly bio-based” as long as it contains more than 95% renewable carbon.

What are Biosurfactants?

Biosurfactants are bio-based surfactants that contain only bio-based, renewable feedstocks AND are produced using sustainable, non-chemical processes. This means the bio content of biosurfactants is 100% renewable carbon. It also means that unlike chemically-produced bio-based surfactants, biosurfactants are produced directly from biological processes of microorganisms.

Biosurfactants can be produced from a variety of organic materials, and they are typically classified by their molecular structure—with varying degrees of complexity.

In short, both the formulation and production of biosurfactants includes fully renewable materials with no hydrocarbon-reliant chemical reactions.

Learn more about the types of surfactants: Putting the FACT in Surfactants: Technical Details

What’s the Difference Between Biosurfactants and Bio-Based Surfactants?

Biosurfactants are a type of bio-based surfactant. Unfortunately, some manufacturers refer to their bio-based surfactants as biosurfactants, further confusing the terminology. It’s important to note that all biosurfactants are bio-based surfactants, but not all bio-based surfactants are biosurfactants.

“It’s important to note that all biosurfactants are bio-based surfactants, but not all bio-based surfactants are biosurfactants.”

There are two key differences between bio-based surfactants and biosurfactants that end users may not realize:

- The bio content

- How the surfactant is produced

Based on these two factors, biosurfactants have proven sustainability and performance advantages compared to bio-based surfactants

Biosurfactants Are More Sustainable Than Bio-Based Surfactants

Biosurfactants are considered environmentally friendly because they are readily biodegradable and 100% biobased. Because of this, they do not require rating through the Renewable Carbon Index. However, if rated, biosurfactants would have the highest possible RCI.

Since biosurfactants are biologically produced, they also do not contain any trace chemicals (such as 1,4-Dioxane or other Proposition 65 chemicals) and minimize any toxicity concerns.

The production process of biosurfactants also exceeds other bio-based surfactants in environmental sustainability. The biological processes used to produce biosurfactants, which typically includes fermentation, require far less energy than chemically-produced, bio-based surfactants, which reduces hydrocarbon use. Biological processes also create fewer toxic byproducts than chemical processes.

Biosurfactants Have Better Multifunctionality Over Bio-Based Surfactants

Biosurfactants have unique structures that deliver excellent interfacial and biochemical properties. Their diverse functionalities offer positive benefits for a multitude of industrial and CPG applications, including as detergents, emulsifiers, wetting agents and dispersants. Biosurfactants can act as primary or secondary surfactants with superior performance and lower in-use rates.

Where Can Formulators Find Biosurfactants?

Many bio-based surfactant suppliers advertise their products as providing an environmentally sustainable alternative to conventional options. But not all bio-based surfactants are created equal. Only biosurfactants minimize environmental impact from production to end use while delivering proven performance gains for CPG and industrial suppliers.

U.S.-based supplier Locus Ingredients produces commercial volumes of biosurfactants. Specifically, the biosurfactant supplier produces sophorolipids (SLP), a type of biosurfactant in the glycolipid class. The biosurfactants are used globally in industrial and CPG applications, including:

- Personal and home care products (available through Dow)

- Industrial and institutional cleaning products (I&I)

- Coatings, adhesives, sealants and elastomers (CASE)

- Metalworking fluids

- Agricultural adjuvants

- Industrial treatments for water, pulp & paper, and textile & leather

The company’s microbial sophorolipids, or glycolipids, are produced using novel fermentation methods with a low carbon footprint and are USDA certified as 100% biobased. The high-activity biosurfactants can be customized to solve a multitude of formulation pain points, including:

- Replacing palm oil-based and petrochemical ingredients

- Minimizing toxicity

- Maximizing product performance

- Reducing carbon intensity

Biosurfactants are Superior Bio-Based Surfactants

In summary, while both bio-based surfactants and biosurfactants offer sustainable alternatives to traditional petrochemical surfactants, biosurfactants stand out as the superior choice. Some bio-based surfactants still rely on fossil fuels for their production, compromising their sustainability. Biosurfactants, especially those produced through fermentation, are 100% biobased, biodegradable, and require less energy for production, making them significantly more environmentally friendly. They also offer enhanced multifunctionality and superior performance across various applications, from personal care products to industrial treatments.

For those seeking the most sustainable and effective surfactant solutions, biosurfactants are the premium option.